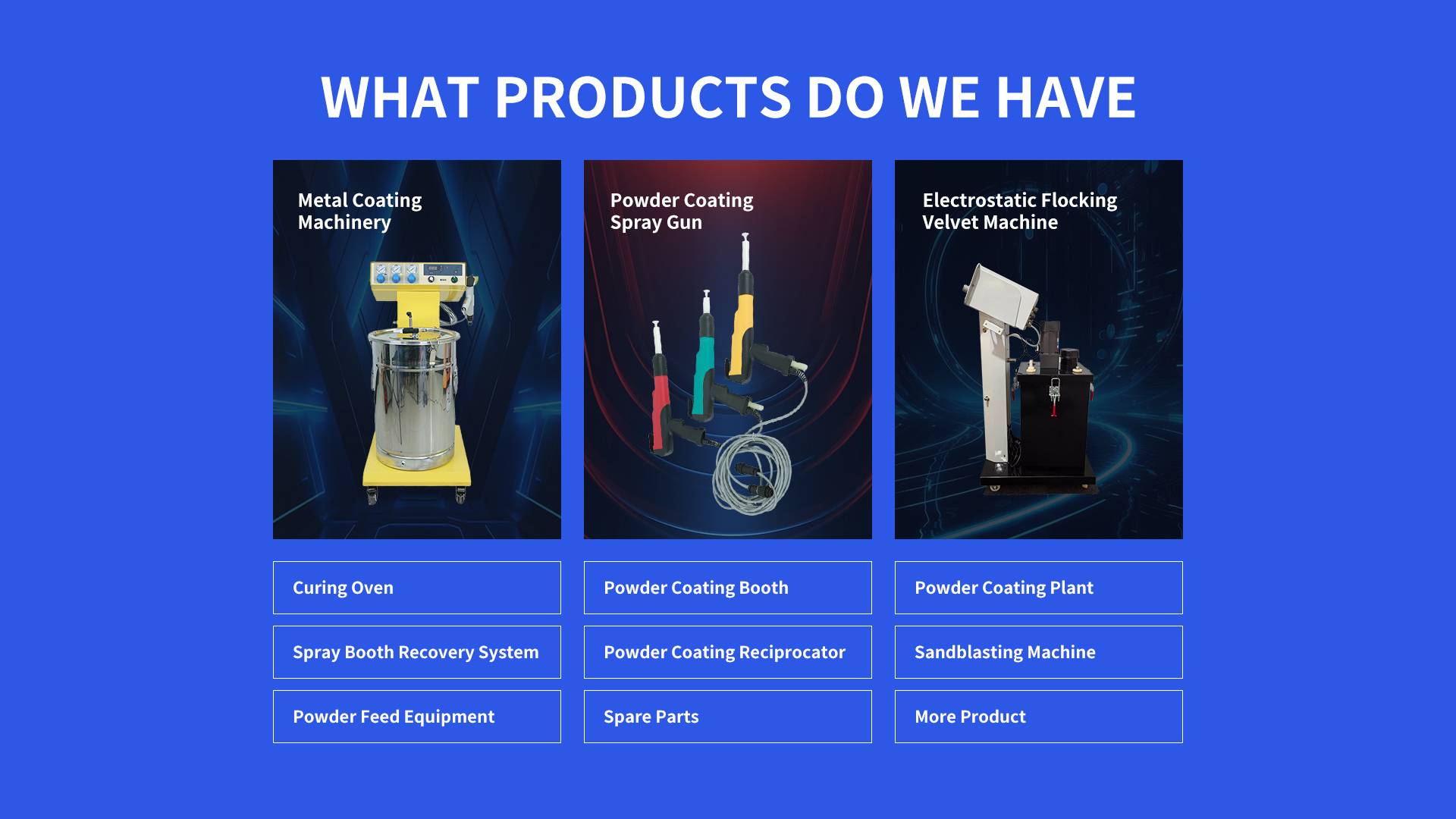

Powder Coating Gun is a vital asset in industrial manufacturing for coating various components. It ensures a consistent and high-quality finish on parts such as gears, shafts, and housings. The Powder Coating Gun's electrostatic technology allows for efficient powder transfer and adhesion, reducing waste and increasing productivity. For example, in an automotive parts factory, the Powder Coating Gun can coat hundreds of engine components per hour.

FAQ:

Q: How accurate is the powder application with the Powder Coating Gun?

A: The Powder Coating Gun offers high accuracy in powder application. The adjustable settings and electrostatic charge help in precisely depositing the powder on the component, ensuring an even and consistent coating thickness.

Q: What maintenance is required for the Powder Coating Gun in an industrial setting?

A: Regular inspection and cleaning of the gun are essential. Check for any clogs in the nozzle, worn-out parts, and ensure proper calibration of the electrostatic system. Lubricate moving parts as needed.

Q: Can the Powder Coating Gun be integrated into an automated production line?

A: Yes, many Powder Coating Guns are designed to be integrated into automated production lines. They can be synchronized with conveyor systems and other machinery for seamless and continuous coating operations.

Title:Powder Coating Gun for Industrial Component Coating

Link:http://www.hpowdercoating.com/pcgal/show/418.html

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com